- Anasayfa

- Research and Laboratories

- Laboratories

- Ceramic Laboratory

Laboratories

- Laboratories

-

- Electronic Materials Laboratory

- Tribology Laboratory

- Casting Laboratory

- Heat Treatment Laboratory

- Chemistry Laboratory

- Corrosion Laboratory

- Ceramic Laboratory

- Metallography Laboratory

- X-Ray Diffraction Laboratory

- Mechanic Laboratory

- Plastic Forming Laboratory

- Advanced Materials Laboratory

- Characterization Laboratory

- Simulation Laboratory

- Specimen Preparation Laboratory

- Composite Laboratory

- Laboratory Coordinators and Personnel

- Laboratory Service Working Systems

Ceramic Laboratory

Aim:

Aim:

The Ceramics Laboratory was founded to research the microstructure-property-performance relation of ceramic materials, observe the factors which affect general behavior in use and preparation, and the production and properties of technical ceramics.

Services

Analyses and Tests

- Drying, heat-treating and sintering of ceramic raw materials and coatings,

- Rheological behavior investigation of ceramic suspensions and solutions,

- Thermogravimetric analysis of ceramic raw materials,

- Specific surface area, pore size distribution and total pore volume measurements,

Analyzes Used in Scientific Research Activities

- Drying, heat-treating and sintering of ceramic raw materials and coatings,

- Rheological behavior investigation of ceramic suspensions and solutions,

- Thermogravimetric analysis of ceramic raw materials,

- Specific surface area, pore size distribution and total pore volume measurements,

Laboratory Infrastructure

- Specific surface area (BET) – Pore Size Distribution Analyzer

- Rheometer

- DTA/TG

- Viscosimeter

- Jet Milling Machine

- Sieve Set (3350-63µm)

- Ultrasonic Cleaner

- Analytical Balance

- Powder mixer

- Pycnometer

- Hydraulic Press

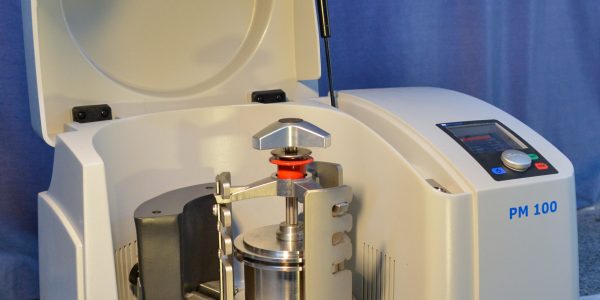

Laboratory Images

Team

Contact

Department of Metallurgical and Materials Engineering