- Anasayfa

- Research and Laboratories

- Laboratories

- Characterization Laboratory

Laboratories

- Laboratories

-

- Electronic Materials Laboratory

- Tribology Laboratory

- Casting Laboratory

- Heat Treatment Laboratory

- Chemistry Laboratory

- Corrosion Laboratory

- Ceramic Laboratory

- Metallography Laboratory

- X-Ray Diffraction Laboratory

- Mechanic Laboratory

- Plastic Forming Laboratory

- Advanced Materials Laboratory

- Characterization Laboratory

- Simulation Laboratory

- Specimen Preparation Laboratory

- Composite Laboratory

- Laboratory Coordinators and Personnel

- Laboratory Service Working Systems

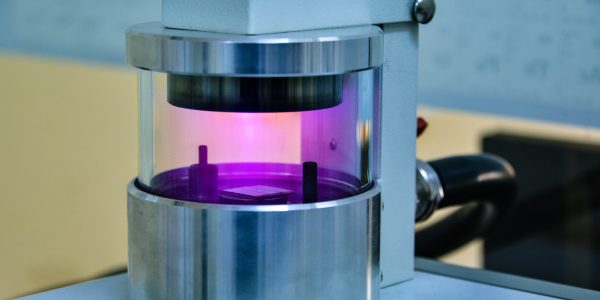

Characterization Laboratory

Aim:

Aim:

SEM laboratory was established to investigate surface morphologies of metallic and non-metallic materials at high magnification and resolution as well as to determine spatial distribution and the amounts of chemical elements (Be-U) in those materials. In addition to failure analysis, microstructure observation of new products is also the aim of this laboratory.

Services

Analyses and Tests

- Coating of non-metallic materials with Au-Pd and C to make them conductive,

- Imaging the surface morphologies of metallic and non-metallic materials by using secondary electrons (SE method),

- Imaging the distribution of light and heavy elements in metallic and non-metallic materials by using back-scattered electrons (BE method),

- Conducting qualitative and semi-quantitative chemical analyses of materials by the EDS method ),

- Providing EDS results in the form of point, line, area analyses and x-ray mapping,

Analyzes Used in Scientific Research Activities

- Coating of non-metallic materials with Au-Pd and C to make them conductive,

- Imaging the surface morphologies of metallic and non-metallic materials by using secondary electrons (SE method),

- Imaging the distribution of light and heavy elements in metallic and non-metallic materials by using back-scattered electrons (BE method),

- Conducting qualitative and semi-quantitative chemical analyses of materials by the EDS method ),

- Providing EDS results in the form of point, line, area analyses and x-ray mapping,

Laboratory Infrastructure

- Au-Pd Coating System

- C Coating System

- Scanning Electron Microscope (SEM) and Energy Dispersive Spectrometer (EDS)

Laboratory Images

Team

Assoc. Prof. Esra DOKUMACI ALKAN

Contact

Department of Metallurgical and Materials Engineering