- Anasayfa

- Research and Laboratories

- Laboratories

- Mechanic Laboratory

Laboratories

- Laboratories

-

- Electronic Materials Laboratory

- Tribology Laboratory

- Casting Laboratory

- Heat Treatment Laboratory

- Chemistry Laboratory

- Corrosion Laboratory

- Ceramic Laboratory

- Metallography Laboratory

- X-Ray Diffraction Laboratory

- Mechanic Laboratory

- Plastic Forming Laboratory

- Advanced Materials Laboratory

- Characterization Laboratory

- Simulation Laboratory

- Specimen Preparation Laboratory

- Composite Laboratory

- Laboratory Coordinators and Personnel

- Laboratory Service Working Systems

Mechanic Laboratory

Aim:

Aim:

The mechanical testing and research laboratory was founded to determine the mechanical properties of materials.

Services

Analyses and Tests

- Tensile, compression and bending tests of materials,

- Hardness measurement of materials,

- Notch impact tests (Charpy & Izod),

- Fatigue tests,

- Strain measurements by using strain gauges.

Analyzes Used in Scientific Research Activities

- Tensile, compression and bending tests of materials,

- Hardness measurement of materials,

- Notch impact tests (Charpy & Izod),

- Fatigue tests,

- Strain measurements by using strain gauges.

Laboratory Infrastructure

- Tensile test machine (5 tons)

- Tensile test machine (25 tons)

- Vickers hardness test machine

- Fatigue machine

- Impact test machine

- Strain machine

Shimadzu AG50 kNG Universal Test Machine (5 tons)

This machine has a 5 ton capacity and tensile, compression and bending tests are available using this machine. The machine is computer-controlled, thus the output of the tests (values, graphics) can be obtained. Also, warm tensile testing up to 550oC can be conducted using a special furnace.

Shimadzu AG-IS Universal Test Machine (25 tons)

This machine has a high load capacity and serves both for the academic research studies as well as for industrial research (public institution, companies etc.). This machine is used only for tensile tests.

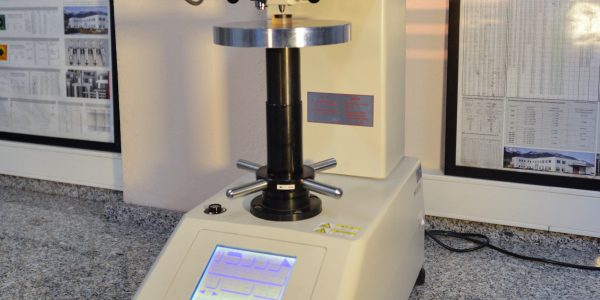

Shimadzu HSV-30 Vickers Hardness Test Machine

With this machine, Vickers hardness measurements of the materials can be done by loading from 200gr up to 30 kg.

Fatigue Machine (Designed by our department):

This machine has a capacity of 1 ton and fatigue tests can be done using compression load at 10 Hz frequency.

AOB FIT 300 EN Impact Test Machine:

This impact machine has a capacity of 300 J. With this machine, Charpy and Izod tests up to -196oC can be conducted.

Strain Machine, National Inst.:

Through the computer, instantaneous values can be recorded with the strain-gauges that are connected to the machine.

Laboratory Images

Team

Contact

Department of Metallurgical and Materials Engineering