- Anasayfa

- Research and Laboratories

- Laboratories

- Tribology Laboratory

Laboratories

- Laboratories

-

- Electronic Materials Laboratory

- Tribology Laboratory

- Casting Laboratory

- Heat Treatment Laboratory

- Chemistry Laboratory

- Corrosion Laboratory

- Ceramic Laboratory

- Metallography Laboratory

- X-Ray Diffraction Laboratory

- Mechanic Laboratory

- Plastic Forming Laboratory

- Advanced Materials Laboratory

- Characterization Laboratory

- Simulation Laboratory

- Specimen Preparation Laboratory

- Composite Laboratory

- Laboratory Coordinators and Personnel

- Laboratory Service Working Systems

Tribology Laboratory

Aims:

Tribology laboratory in Dokuz Eylul University Department of Metallurgical & Materials Engineering was established to carry out world leading research and development in tribology and surface engineering to support industry and society. The combined expertise of the Mechanical and Materials departments allows it to encompass all aspects of Tribology with research ranging from nano-scale coatings to lubrication of large structures and machines. The laboratory has expertise in many of the facets of Tribology.

Services

Analyses and Tests:

- Characterization of friction and wear in various working conditions

- Measurement of wear loss and friction coefficient values

- Determination of surface roughness

- 3D surface profiling

- Investigation of the tribocorrosion behavior of metallic materials

- Measurement of coating thickness

Analyzes Used in Scientific Research Activities

- Characterization of friction and wear in various working conditions

- Measurement of wear loss and friction coefficient values

- Determination of surface roughness

- 3D surface profiling

- Investigation of the tribocorrosion behavior of metallic materials

- Measurement of coating thickness

Laboratory Infrastructure:

- Tribometer (CSM Instruments standard tribometer)

- Friction and wear test machine (Plint TE88)

- Surface roughness tester (Mitutoyo SJ301)

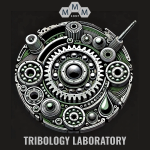

- High resolution surface profilometer (Ambios Technology XP-2)

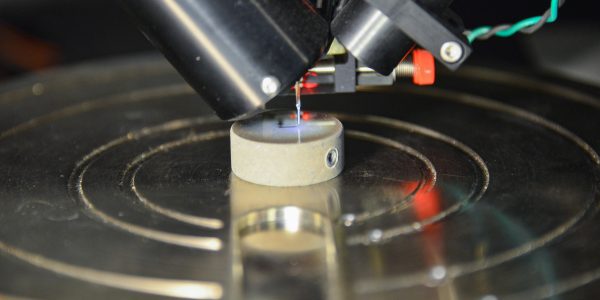

Friction and Wear Test Machine (Plint TE 88 ):

Wear and friction tests are performed using Plint TE 88 wear and friction test machine according to ASTM F 732 (reciprocating mode), ASTM G 99 (Pin on Disc), ASTM G 77 (Block on Rig) standards in various test conditions (dry, lubricated or corrosive environment). The temperature of test specimens is increased up to 200 °C. Variation of friction coefficient and wear loss is recorded via a computer based software Compend 2000. It is also allowed to change the test parameters such as time, frequency, and temperature by this software. In addition, tribocorrosion (or corrosion-wear) tests of metallic materials are performed using Princeton Applied Research VersaStat 3 potentiostat which allows to investigate the synergistic effect of wear and corrosion acting together. Tribocorrosion behaviour of biomaterials and passivity properties of metallic materials used in nuclear energy stations are investigated in various corrosive environments.

High Resolution Surface Profilometer:

Surface roughness measurement with surface profilometer is a common method. Roughness is determined with the gentle surface (0.05 mg lowest applied load) scan through the use of a stylus.

Laboratory Images

Team

Asst. Professor Bahadır UYULGAN

Contact

Department of Metallurgical and Materials Engineering